The advantages and limitations of rotary vacuum drum filter compared to other separation methods are: The separation of the mycelia from the fermentation liquor in the manufacture of antibiotics.

Examples of pharmaceutical applications include the collection of calcium carbonate, magnesium carbonate and starch.If the slurry contains considerable amount of solids, that is, in the range of 15-30%.The rotary filter is most suitable for continuous operation on large quantities of slurry.At the final step of the separation, the cake is discharged as solids products and the drum rotates continuously to another separation cycle. The cake is dry because the vacuum drum is continuously sucking the cake and taking the water out of it.

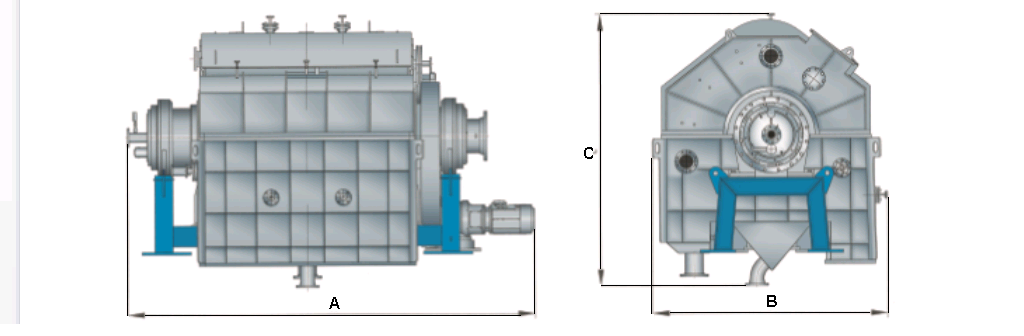

When the cake is rotating out, it is dewatered in the drying zone. The drum is suspended on an axial over a trough containing liquid or solids slurry with approximately 50-80% of the screen area immersed in the slurry.Īs the drum rotates into and out of the trough, the slurry is sucked on the surface of the cloth and rotated out of the liquid or solids suspension as a cake. It offers a wide range of industrial processing flow sheets and provides a flexible application of dewatering, washing and/or clarification.Ī rotary vacuum filter consists of a large rotating drum covered by a cloth. Rotary vacuum drum filter (RVDF), patented in 1872, is one of the oldest filters used in the industrial liquid-solids separation. 7 Necessary post treatment for waste stream for clarifierīasic fundamentals Rotary vacuum drum filter.6 Necessary post treatment for waste stream for thicker.5.2.6 Pre coat filter operation heuristics.5.2 Discharge mechanism adjustment heuristics.

0 kommentar(er)

0 kommentar(er)